ULTIMATE ADDONS FOR DIVI BUILDER

Make your workflow faster with custom Divi Builder Add-ons and Child Themes

Are you looking to speed up web design work?

Divi WordPress page builder is the market leading tool that can help you design stunning web pages in no time! It’s got a visual page builder interface that’s very intuitive for any level of WordPress user. You can achieve almost any layout in mind with its powerful drag and drop builder components. Our collection of ‘Ultimate’ Divi products enable you to take the power of Divi page builder to next level. Divi builder works well with almost all popular WordPress themes. Use ‘Divi or Extra‘ theme (Divi builder is packed inside these themes) for best results.

Are you new to Divi? Learn how to use it from our WordPress learning facility. Start Here….

Our Popular Divi Products

We at divibuilderaddons.com make various add-on solutions to Divi builder/theme. These include Divi child themes, plugins, modules and layouts. Our products have been featured several times on the Elegant Themes blog. We are known for our future-proof products, and excellent customer support (see what others are saying).

We’ve been providing Divi solutions since late 2016… BUY WITH CONFIDENCE!

-

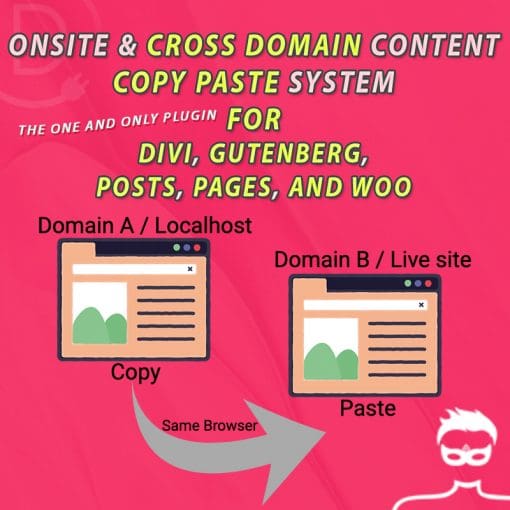

Cross-Site Divi/Gutenberg Content Copy Paste System (CCPS)

$59.00 -

Divi Creative Child Theme

$59.00 -

Divi Full Page Scrolling Framework Child Theme

$59.00 -

Divi Ribbon Module for Visual Builder

$35.00 -

Sale!

Divi Super Power Bundle Deal

Original price was: $491.00.$159.00Current price is: $159.00. -

Divi Timeline Module for Visual Builder

$35.00 -

Heights Divi WooCommerce child theme

$39.00 -

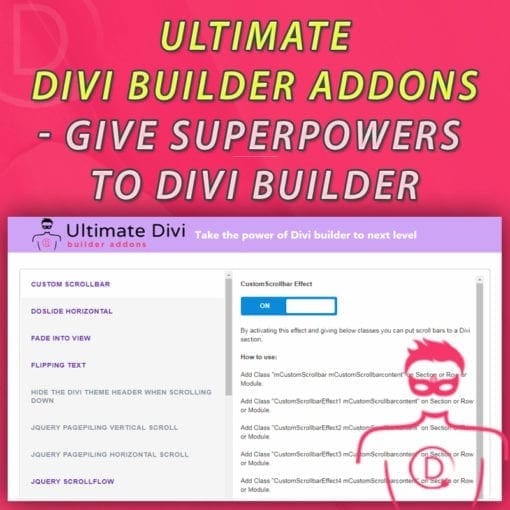

Ultimate Divi Builder Addons – Give superpowers to Divi

$59.00

Let’s build something awesome!

Products On Sale!

Occasionally we offer discounts for our products. Watch this space for great bargains.

Frequently Asked Questions

What is required to use our Divi Addon products?

You will need to have either Divi Builder or Divi/Extra Theme installed and activated in your WordPress web site.

All our products require to have PHP version 5.5 or higher installed in your server

All our products require to have PHP version 5.5 or higher installed in your server

Can I use Divi Addons on client sites?

You can use our products for both personal and commercial use on a unlimited Websites (unless otherwise stated under ‘Terms of sale’ in each product).

For how long do I get product support and update?

You get product updates for lifetime (For purchases made through our website only).

…….

We provide customer support for life of the product – Support is provided for bug fixes only. If you need customisation support you will have to pay our hourly rate.

…….

We provide customer support for life of the product – Support is provided for bug fixes only. If you need customisation support you will have to pay our hourly rate.

Scope of Support – Our main intention by providing product support is to help uncover bugs, add frequently requested features and overall improve the product for everyone. We reserve the right to dismiss any support request that’s outside of this support scope.

Will Divi Addons slow down my website?

Absolutely not. We build our Divi products with performance in mind. It’s built to the standards of Divi Builder and hence, no code bloat.

How do I update Divi Addons?

We will make every attempt to ensure that our products are compatible with all future releases of Divi. You can access product updates through your website admin dashboard or you can directly download updated Zip packages from your ‘My Account‘ Page.

What is your refund policy?

Due to the nature of digital products as they cannot be returned, it’s impossible to prevent fraud and still offer refunds. Hence refund requests are expressly denied. You can use our test drive facility to check the product before you make purchase.